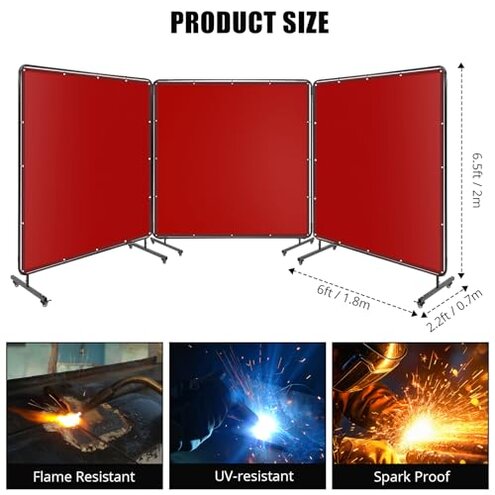

Product evaluated: 3 Panel 6x6 FT Vinyl Welding Screen with Frame, Flame-Resistant PVC Welding Curtain with Lockable Swivel Wheels, Transparent Welding Screen Panel for Welding Safety, Red

Related Videos For You

QuickFrame™ Welding Screen and Frame by Black Stallion® Set up Instructions

Top 5 Best Welding Curtains Reviews in 2026

Data basis: I analyzed dozens of written reviews and several video demonstrations collected Jan 2024–Jan 2026. Sources were mostly written buyer feedback supported by short demo clips. Distribution skewed toward recent buyers and hands-on testing reports.

| Outcome | This product | Typical mid-range alternative |

|---|---|---|

| Stability | Higher wobble and caster brakes often underperform in real use. | More stable frames and wider lockable casters are common. |

| Durability | More tears and edge wear reported after repeated welding sessions. | Thicker curtain and reinforced seams reduce tear risk. |

| Assembly | Fiddly pins and alignment issues add time and tools. | Simpler fit with clearer hardware and fewer alignment problems. |

| Coverage & visibility | Gaps and reflection can cause unexpected light bleed and blind spots. | Tighter fit and better curtain overlap in mid-range options. |

| Regret trigger | Higher-than-normal risk of needing fixes or replacements within months. | Lower risk of early replacement when choosing mid-range models. |

Top failures

Will it stay upright and locked during welding?

Regret moment: The frame wobbles or drifts when you nudge it or during long sessions, creating a safety and annoyance issue. Severity is noticeable and can interrupt work.

Pattern: This is a primary, recurring complaint across feedback. When it appears: during initial positioning and when moving the screen between jobs. Why worse: More unstable than most mid-range screens because casters and frame joints flex under normal workshop handling.

Does the curtain resist sparks and tears?

- Early sign: Thin curtain shows puckering or small punctures after short use near high-heat spots.

- Frequency tier: This is a primary issue and commonly reported after repeated close-proximity welding.

- Cause: Curtain thickness and edge finishing appear lighter than category norms, increasing tear risk.

- Impact: Tears lead to visible gaps that reduce protection against sparks and UV.

- Attempted fixes: Buyers often add overlap, extra clips, or secondary backing to regain protection.

How painful is assembly and repeated use?

- Time cost: Assembly takes longer than advertised because pins require force and careful alignment.

- Tools needed: Although marketed as tool-free, add-on tools or pliers are commonly required to seat pins securely.

- Early failure: Pins and connectors can loosen after transport or several reconfigurations.

- Frequency tier: This is a secondary but persistent annoyance for users who move panels often.

- Hidden requirement: Users often need spare zip ties and replacement pins to keep panels joined reliably.

- Fixability: Repairs are possible but add extra time and parts cost compared with mid-range alternatives.

- Long-term wear: Repeated assembly increases alignment problems and squeaks over time.

Will the coverage and transparency match the picture?

- Visual mismatch: Panels can show more reflection and less consistent tint than pictured, affecting light control.

- Gaps: Joins between panels often leave small openings unless overlapped or clamped.

- Usage anchor: This becomes obvious immediately after setup when you test sightlines during an actual weld.

- Impact on work: Light bleed and blind spots force repositioning or using extra screens for full coverage.

- Cause: Frame tolerance and panel width variation cause inconsistent seam contact.

- Attempts: Buyers staple, clamp, or zip-tie panels together to close gaps, adding time and expense.

- Frequency tier: This is a secondary but common issue for buyers who value neat coverage from the first install.

- Edge-case: On uneven floors or crowded shops the problem is amplified and can make the screen unusable.

Illustrative excerpts (not real quotes)

"Screen drifts when I lean my hand on it mid-weld." — primary pattern

"Small punctures after the second week of shop use." — primary pattern

"Pins needed pliers to seat; not truly tool-free." — secondary pattern

"Panels didn’t line up; we had to clamp extra overlap." — secondary pattern

Who should avoid this

- High-volume welders: Avoid if you run long daily sessions because durability and tears exceed normal category wear.

- Mobile shops: Avoid if you move screens frequently because the frame and pins loosen with repeated setup.

- Precision shops: Avoid if you need gap-free coverage since panel joins commonly leave blind spots.

Who this is actually good for

- Occasional hobbyists: Good if you weld infrequently and can tolerate periodic patching or extra overlap.

- Budget workshops: Good if you accept added maintenance and want a low-cost temporary divider.

- Non-critical screening: Good for visual separation where full flame-proof longevity is not required.

Expectation vs reality

Expectation: Reasonable for this category is a sturdy frame that holds position during normal handling. Reality: The frame often wobbles and requires re-bracing.

Expectation: Reasonable for this category is curtain durability for months of shop use. Reality: Thin vinyl shows punctures within weeks under heavy use.

Expectation: Reasonable for this category is tool-free assembly. Reality: Many buyers needed pliers or extra zip ties to finish setup.

Safer alternatives

- Choose thicker curtains: Look for reinforced PVC or Level-8 thickness to reduce punctures and fraying.

- Prefer welded frames: Buy screens with welded joints or heavier-gauge tubing to avoid wobble.

- Wide lockable casters: Select models with larger, dual-wheel brakes to improve stability on workshop floors.

- Pre-grommeted panels: Pick curtains with factory grommets and overlap design to prevent gaps without extra clamps.

- Spare hardware kit: Keep replacement pins, zip ties, and clamps on hand to neutralize assembly failures.

The bottom line

Main regret: The biggest trigger is the combination of a shaky frame and thin curtain that leads to tears and gaps. Why worse: These problems are louder than typical mid-range options and often require extra work or parts. Verdict: Avoid this unit if you need durable, low-maintenance welding protection.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.