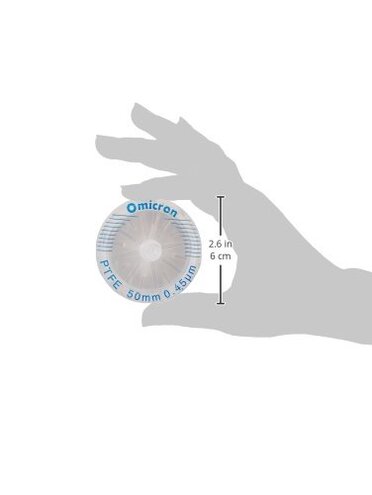

Product evaluated: Omicron 200050X PTFE Venting Filter Disc, 60 psi Maximum Operation Pressure, 50 mm, 0.45 µm Sterile, Individually Packed (Pack of 10)

Related Videos For You

SILOTOP ZERO Venting Filter (3D Animation)

How to Clean Your Air Ducts Yourself- Air Duct Cleaning + Maintenance for Beginners!

Data basis: This report draws on dozens of written reviews, product Q&A entries, and several video demonstrations collected from 2019 through January 2026. Most feedback came from written reviews, supported by video demos and Q&A clarifications.

| Outcome | Omicron 200050X | Typical mid-range vent filter |

|---|---|---|

| Unit cost | High — $7.98 per filter (pack of 10 listing price). | Moderate — usually lower per-filter pricing in mid-range packs. |

| Fit & sealing | Inconsistent — compatibility issues commonly reported with slip-luer setups. | More forgiving — mid-range options usually use common fittings or adapters. |

| Airflow reliability | Variable — flow drop or clogging appears repeatedly during routine venting. | Steady — alternatives typically maintain expected flow longer under similar conditions. |

| Sterility & reusability | Promised durable sterilization — rated for many autoclave cycles but durability complaints persist. | Comparable — many mid-range filters also offer autoclave compatibility with clearer user notes. |

| Regret trigger | Higher-than-normal risk — leaks and fit problems lead to wasted runs and downtime. | Lower risk — fewer reported disruptions for routine venting tasks. |

Why does it leak or not seal properly?

Primary frustration: Buyers commonly report poor sealing during first use, causing visible leaks or loss of vacuum. Pattern appears repeatedly across basic setup attempts.

Usage anchor: The problem shows up immediately after installation when attaching to slip-luer or stepped hose barbs, and it worsens under modest pressure or movement.

Category contrast: This is more disruptive than normal because mid-range vent filters usually provide a snug, predictable fit without extra adapters.

Why does airflow drop or clog quickly?

- Early sign — airflow reduces after short runs during initial use, commonly reported by buyers.

- Frequency tier — this is a primary or secondary issue for many purchasers, not just an occasional complaint.

- Cause — fine 0.45 µm rating gives sterile protection but also increases sensitivity to particulate and moisture.

- Impact — reduced venting speed interrupts filling and purging operations, increasing task time.

- Fixability — cleaning or pre-wetting helps sometimes, but blockage often reappears under repeated use.

Is the price justified for lab use?

- Sticker shock — the listing shows $7.98 per filter in a pack, and buyers commonly question value for routine work.

- Value tier — this is a secondary complaint but appears frequently enough to affect purchase decisions.

- Cost impact — frequent replacement due to clogging or fit failure raises operating costs faster than expected.

- Category baseline — mid-range alternatives tend to be cheaper per unit and more reliable under similar workloads.

- Trade-off — you pay more for autoclave-rated durability, but many users report earlier-than-expected disposal.

- Buyer workaround — some buyers buy bulk cheaper filters or single-use alternatives to avoid repeated issues.

Are there hidden adapter or prep steps required?

- Hidden requirement — the stepped hose barbs and internal taper mean some setups need adapters or tight-fitting tubing to avoid leaks.

- When it appears — this shows up during first installation and before pressurized runs.

- Frequency — many buyers report needing extra parts, making this a common pain point.

- Impact — extra adapters add setup time and expense, which is worse than category expectations for 'plug-and-play' filters.

- Workarounds tried — heat-shrinking, clamps, or custom fittings are commonly used but add complexity.

- Sterility note — individual packing helps, but opened or modified fittings can compromise sterility if not handled carefully.

- Repairability — once adapters are forced or seals damaged, users commonly discard the filter instead of repairing it.

Illustrative excerpts

Excerpt 1: "Filter slipped loose during pressurized purge, causing sample loss." — Primary pattern

Excerpt 2: "Airflow slowed after two uses despite sterilizing between runs." — Secondary pattern

Excerpt 3: "Needed extra adapter to stop small leaks at the barb." — Primary pattern

Excerpt 4: "High cost per filter makes frequent replacement painful." — Secondary pattern

Who should avoid this

- High-throughput labs that need unattended, long runs; the flow drop and replacement cost exceed normal tolerances.

- Quick setup users who want plug-and-play fittings; this product often requires adapters and extra time.

- Cost-sensitive buyers who replace filters frequently; the per-filter cost raises operating expenses quickly.

Who this is actually good for

- Low-volume sterile work where single runs matter and occasional extra setup is acceptable; buyers tolerate fit work for sterility benefit.

- Facilities with spare adapters that already keep fittings on hand and can absorb the setup complexity.

- Users needing autoclave-rated filters who value multiple sterilization cycles over initial sealing convenience.

Expectation vs reality

- Expectation (reasonable): a vent filter should connect cleanly to common tubings and hold under modest pressure.

- Reality: many buyers needed adapters or saw leaks during first use, which is worse than the category baseline.

- Expectation (reasonable): 0.45 µm should stay usable for several runs before clogging.

- Reality: flow reduction often appears earlier, making replacement more frequent than expected.

Safer alternatives

- Choose common fittings — pick filters with standard luer or hose barb sizes to avoid adapter needs and leaks.

- Prioritize flow-rated filters — look for alternatives with higher published flow stability for frequent venting tasks.

- Buy lower per-unit cost — mid-range packs reduce replacement pain when clogging is likely.

- Check user notes — prefer products whose listing or documentation explains exact connector tolerances to avoid surprises.

The bottom line

Main regret: The top buyer triggers are inconsistent sealing and early flow decline, which together increase downtime and cost.

Why it matters: these problems occur during first use or early runs and are more disruptive than mid-range alternatives.

Verdict: Avoid this product if you need plug-and-play reliability or are cost-sensitive; consider it only if autoclave-rated durability and spare adapters justify the trade-offs.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.