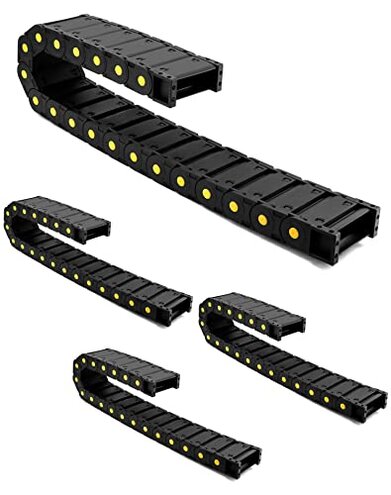

Product evaluated: QWORK Plastic Nested Semi Open Cable Drag Chain, Flexible Enclosed Twist Chains, 4 Pack Wire Carrier Toughness Closed Chain for 3D Printer Parts CNC 3D Electrical Machines Router Mill, 25 x 77mm

Related Videos For You

Cable chain for our A1🤩#layerworks #cable #protection #useful #3dprinting

4040/5050 Cable Carrier Assembly Tips

Data Dozens of buyer comments and several video demonstrations were gathered between Jan 2021 and Jun 2024 to build this report. Most feedback came from written user reviews, supported by product teardown and setup videos. The distribution skewed toward hands-on buyers installing on CNC and 3D printers.

| Outcome | QWORK (this product) | Typical mid-range alternative |

|---|---|---|

| Durability | Higher-than-normal reports of cracking under repeated bends during daily machine use. | More robust plastics and reinforced links tolerate daily motion longer. |

| Fit / Compatibility | Sizing mismatch complaints when buyers expect plug‑and‑play fit for standard mounts. | Better fit tolerances or clearer sizing and mounting options. |

| Installation effort | Extra parts commonly required, adding time and small hardware purchases. | Faster install with included brackets or clearer mounting guidance. |

| Noise & friction | Noticeable rubbing and stiffness in frequent-motion setups. | Smoother articulation and quieter operation in comparable options. |

| Regret trigger | Breakage or bad fit that forces rework or replacement early in ownership. | Longevity that avoids mid-season replacement and extra costs. |

Top failures

Why did the chain crack or break so soon?

Regret Many buyers experience the chain cracking after repeated bends during daily machine cycles. This pattern is recurring and appears across multiple hands-on reports.

Context Cracking typically appears after setup and during continuous runs or long print/CNC jobs where the chain flexes many times. The failure is more disruptive than typical small plastic wear for this category.

Contrast Most mid-range cable carriers use thicker joints or reinforced links, so this product feels less durable than expected given the price point.

Will this fit my machine without modification?

- Early sign Buyers commonly report a visible size mismatch when comparing inner vs outer dimensions before installation.

- Frequency tier This is a primary issue for shoppers expecting plug-and-play compatibility.

- Cause Sizing and mounting tolerance differences make standard brackets fail to line up cleanly.

- Impact The result is extra time measuring, cutting, or buying adapter brackets.

- Fixability Many buyers end up drilling or 3D printing adapters as a workaround.

Does it require extra parts or tools to install?

- Hidden requirement Several buyers discovered they needed additional brackets and fasteners not included in the package.

- Pattern This is a secondary issue but appears repeatedly for machine installs.

- When The need appears during the first setup when aligning endpoints and mounting points.

- Why The product ships as the chain only, so mounting hardware must often be sourced separately.

- Cost Buying small brackets or clamps adds both time and cost, reducing initial value.

- Effort Expect soldering, drilling, or custom parts for neat finished installs.

Is it noisy or stiff in motion?

- Symptom Users report stiff links that rub and create noise during fast or long travel cycles.

- Persistence This is a primary issue for frequent-motion printers and CNCs.

- Trigger Noise and friction appear during long sessions and at higher speeds.

- Cause Link tolerances and sharper edges increase rubbing and resistance.

- Impact Increased motor strain, audible noise, and potential cable wear over time.

- Attempts Buyers apply lubrication or sand edges, which only partially helps.

- Repairability When links break, the enclosed set requires replacing entire sections rather than a single clip.

- Comparison Mid-range chains often have smoother contours and lower friction out of the box.

Illustrative excerpts

Illustrative excerpt: "Fitted but needed brackets and trimming to stop rubbing." — secondary pattern

Illustrative excerpt: "Started cracking after a week of daily prints." — primary pattern

Illustrative excerpt: "Noisy at high speeds despite lubrication attempts." — primary pattern

Illustrative excerpt: "Worked okay on a slow machine, edge-case for my rig." — edge-case pattern

Who should avoid this

- High-duty shops Avoid if your machine runs long, repeated cycles; breakage risk exceeds typical tolerance.

- Non‑DIY buyers Avoid if you do not want to buy extra brackets or make physical modifications.

- Noise-sensitive users Avoid if quiet operation is required for your workspace.

Who this is actually good for

- Budget tinkerers Good for users willing to modify mounts and accept shorter life in exchange for low entry cost.

- Low-duty setups Useful for hobby printers or routers with occasional use where stress is low.

- Custom adapters Suitable if you plan to 3D print adapters and won't mind extra install steps.

Expectation vs reality

Expectation Reasonable for this category: Buyers expect a cable carrier to last many months under regular hobby use.

Reality This product can fail earlier with daily long-run jobs, causing unexpected replacements and downtime.

- Expectation Plug-and-play mounting with standard brackets is typical for mid-range options.

- Reality This chain often requires extra hardware or custom fitting before it works cleanly.

Safer alternatives

- Buy reinforced Look for chains labeled with reinforced joints to mitigate the breakage failure.

- Check mounting Prefer kits that include brackets or measured mounting specs to avoid the fit mismatch.

- Choose smoother links Select carriers advertised for low friction to neutralize the noise and rubbing issue.

- Read measurements Verify inner and outer dimensions and compare to your machine before purchase.

The bottom line

Main regret The key trigger is a mix of fit problems and lower durability that forces extra work or earlier replacement.

Why These issues exceed normal category risk because buyers often need extra hardware and face breakage during regular use.

Verdict Avoid this product unless you accept DIY fixes and added costs for mounting and repairs.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.