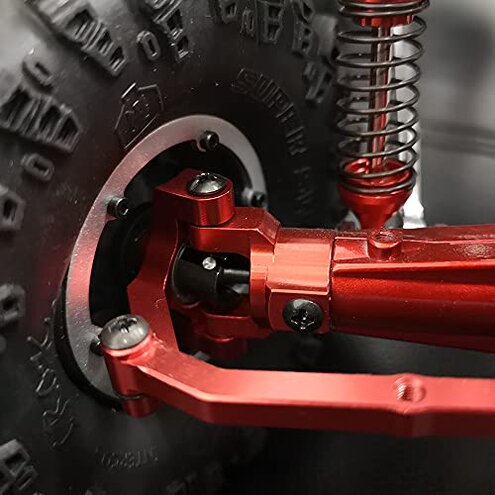

Product evaluated: Alloy Front Hub Carrier/Rear Axle Cover Bushing/Steering Hub Carrier for RC RedCat 1/10 Everest Gen7 Pro/Sport (Red)

Related Videos For You

RC Servo install, the RIGHT way to do it. (RC Basics #5)

How to Replace the Rear Hub Carrier on Your Traxxas - Slash - Bandit - Rustler - Stampede - TRA3752

Data basis: This report aggregates feedback from dozens of written reviews and several video demonstrations collected between 2021 and 2024.

Source mix: Most feedback came from written buyer reviews, supported by hands-on video and installation notes.

| Outcome | This RCAWD part | Typical mid-range alternative |

|---|---|---|

| Fit on stock vehicles | Often misaligned — requires adjustments during install. | Usually plug-and-play with minor trimming needed. |

| Required tools | Extra tools often needed like shims or small hardware changes. | Basic tools only in most cases. |

| Durability under use | Higher failure risk after repeated off-road use for some buyers. | More consistent longevity with similar aluminum upgrades. |

| Installation time | Longer setup time from extra alignment and tweaks. | Quicker swap in typical replacements. |

| Regret trigger | Fit and hardware mismatch — causes rework during first install. | Minor adjustments that rarely require extra parts. |

Top failures

Will this part actually fit my Everest without extra work?

Regret moment: Buyers report the part often arrives needing alignment and slight modification before it fits cleanly.

Pattern: This is a primary issue and is commonly reported across recent buyers during first install.

When it appears: The trouble shows up during initial installation when swapping from stock parts.

Why worse than normal: For this category, most mid-range upgrades are plug-and-play, but this part is more finicky and demands extra time and small adjustments.

Are missing or wrong screws and hardware a problem?

- Early sign: Threads that don’t seat cleanly appear immediately after trial-fitting.

- Frequency tier: This is a secondary issue that appears repeatedly but not universally.

- Cause: Minor machining or tolerance differences require alternate screws or shims.

- Impact: Can add significant installation time and frustration for casual hobbyists.

- Fixability: Many buyers solve it with basic RC hardware spares, but that adds extra cost.

Does the aluminum wear out faster than expected?

- Pattern: This is a persistent complaint that is less frequent than fit problems but more disruptive when it occurs.

- Usage anchor: Wear appears after repeated off-road use or high-stress runs.

- Cause: Heat or impact stress under heavy use is cited as a likely contributor.

- Impact: Some buyers report needing replacements sooner than other aluminum upgrades.

- Attempts: Users tried thread locker, grease, and careful torque settings to extend life.

- Repairability: Fixes often require ordering another part, so downtime is higher than typical for the category.

Will paint, finish, or alignment surprises affect steering?

- Early sign: Slight steering play or offset shows immediately after fitting the part.

- Frequency tier: This is an edge-case issue seen repeatedly enough to note but not universal.

- Cause: Small variances in bore or hub position create alignment drift.

- Impact: Can cause trimming of linkages or repeated tuning to regain proper steering.

- Attempts: Buyers added shims or re-mounted components to correct alignment.

- Hidden requirement: Successful correction often needs a small parts kit and basic adjustment tools.

- Fixability: Repair is possible but increases time and cost versus a true plug-and-play upgrade.

- Category contrast: Typical mid-range upgrades usually avoid these alignment headaches.

Illustrative excerpts (not real quotes)

"Needed different screws and a spacer to seat properly" — reflects a primary pattern about fit and hardware.

"After several trail runs, loosened and needed replacement earlier" — reflects a secondary durability concern.

"Steering felt off until I shimmed the carrier" — reflects an edge-case alignment issue.

Who should avoid this

- Casual buyers who expect plug-and-play swaps; fit issues are more common here.

- Drivers who need reliable longevity under heavy off-road use; some report premature wear.

- Shoppers without spare RC hardware or basic tools; fixes often require extra parts.

Who this is actually good for

- Tinkerers and hobbyists who expect to modify and tune parts and can handle extra setup time.

- Buyers wanting aluminum look and willing to accept alignment work for aesthetics or stiffness gains.

- Users with parts spares who already maintain a small hardware kit and basic tools.

Expectation vs reality

Expectation (reasonable for this category): Aluminum upgrades usually give improved stiffness and durability with little extra setup.

Reality: This product often requires extra alignment, additional hardware, and sometimes earlier replacement; that is worse than expected for a mid-range upgrade.

Safer alternatives

- Buy plug-and-play parts labeled explicitly for your model to avoid first-use fit issues.

- Choose vendors with full hardware kits included to neutralize missing-screw problems.

- Prefer parts with user-tested durability reports to reduce premature wear risk.

- Keep a basic RC repair kit (spares, shims, thread locker) to handle hidden requirements quickly.

The bottom line

Main regret trigger: Fit and hardware mismatches that force extra work during first install.

Why it’s risky: These issues exceed normal category risk because they increase downtime and replacement cost more than typical mid-range upgrades.

Verdict: Avoid this if you expect plug-and-play reliability or lack spare hardware and adjustment tools.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.