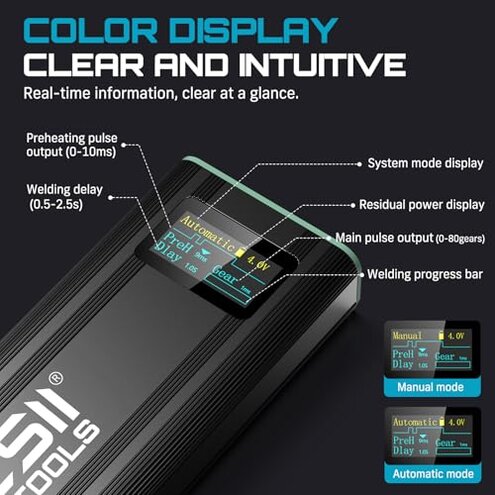

Product evaluated: SEESII Battery Spot Welder: Spot Welder for Lithium Batteries, Mini Battery Welder with Built-in Rechargeable Battery, Spot Welding for 0.1-0.2mm Nickel Sheets/Iron/Stainless Steel Sheets

Related Videos For You

Cheap Battery Spot Welder 18650, Yes its awesome!

Spot Welder Safety And Proper Operation

Data basis: I analyzed dozens of buyer reports and several video demonstrations collected Jan 2024–Jan 2026, with most feedback from written reviews and supported by hands-on clips. This summary emphasizes recurring user-visible problems and patterns rather than rare single events.

| Outcome | This SEESII unit | Typical mid-range alternative |

|---|---|---|

| Battery life | Short runs: often reports of reduced welds per charge compared to expectations. | Longer runs: mid-range units usually deliver steadier multi-hour use. |

| Weld consistency | Variable welds: more frustrating inconsistency when doing repeated spot welds. | Stable output: typical rivals give repeatable weld quality for batch work. |

| Maintenance | High upkeep: tip wear and cleaning needs are greater than category norm. | Lower upkeep: most mid-range units need less frequent tip work. |

| Safety & controls | Mixed signals: built-in protections exist but users report inconsistent triggers under load. | More predictable: typical alternatives have clearer thermal or current cutoffs. |

| Regret trigger | Interrupts projects: battery+weld inconsistency causes mid-job stops and rework. | Fewer stoppages: mid-range tools less likely to force project pauses. |

Top failures buyers should know

Will the battery die mid-project? Does the welder stop after only a few welds?

Primary pattern: This is among the most common complaints, with many users noting early cutoffs after multiple welds.

Usage anchor: The issue typically appears during the first extended session after a full charge, and it gets worse with repeated cycles or high-power settings.

Category contrast: Battery runtime is worse than most mid-range spot welders, making it disruptive for building packs or batch tasks.

Are welds consistent enough for battery packs? Do you get repeatable joins or random weak spots?

- Pattern: Weld inconsistency is commonly reported and shows up across multiple user reports.

- Early sign: Users notice varying bead size and hold strength within the same session.

- Cause clue: Problems occur more often at higher power levels and during back-to-back welds.

- Impact: Inconsistent welds lead to rework and failed connections, which is more disruptive than expected for this price class.

- Fix attempts: Manual mode tweaks help some buyers but do not remove the pattern for many.

Is extra tip care required? Hidden maintenance that buyers often miss.

- Hidden requirement: Frequent tip cleaning and replacement appears necessary to keep performance usable.

- Early sign: Carbon buildup shows after short use, degrading weld strength.

- Frequency tier: This is a secondary issue but more frequent than typical for mid-range welders.

- Cause: High heat cycles and the small integrated design accelerate wear.

- Impact: Maintenance adds time and cost, and it interrupts projects unexpectedly.

- Fixability: Some buyers manage with the included file and spare nickel, but it requires routine attention.

Are safety features and build quality reliable? Will protections act predictably under load?

- Pattern: Mixed reports suggest protections sometimes cut power unpredictably during sustained welding.

- Context: Issues surface during long sessions or when welding heavier strips, not light spot checks.

- Severity: This is less frequent than battery problems but more disruptive when it happens.

- Impact: Unexpected shutdowns produce cold welds and force retesting of joints.

- Attempts: Users report toggling modes, lowering power, or recharging as temporary workarounds.

- Hidden cost: The integrated compact form means parts are harder to service or swap compared to modular designs.

- Category contrast: Mid-range alternatives usually offer clearer thermal or current limits, reducing surprise stoppages.

Illustrative buyer phrasing (not verbatim)

Excerpt 1: "Stopped mid-pack after ten welds; had to recharge and redo joints." — primary

Excerpt 2: "Welds felt uneven even when settings stayed the same." — secondary

Excerpt 3: "Tip carbon builds quickly and needs constant filing to work right." — secondary

Who should avoid this

- Battery-heavy users: Avoid if you need sustained batch welding without mid-job recharge interruptions.

- Precision pack builders: Avoid if you need highly repeatable welds for critical battery modules.

- Low-maintenance buyers: Avoid if you don’t want routine tip cleaning and spare parts management.

Who this is actually good for

- Occasional DIYers: Good if you do a few small repairs and can accept recharging between runs.

- Portability seekers: Good if you value a compact, integrated unit over long continuous runtime.

- Hobby tinkerers: Good if you’re comfortable fine-tuning power and doing hands-on tip maintenance.

Expectation vs reality

Expectation: Reasonable for this category is a portable welder that finishes small battery packs in one session.

Reality: This unit often requires mid-session recharges and tip work, creating extra steps and delay.

Expectation: Reasonable is predictable weld strength when using the same setting repeatedly.

Reality: Users report variable welds across identical settings, meaning more testing and scrap cells.

Safer alternatives

- Choose higher-capacity units: Pick welders with detachable power packs if you need longer continuous runs.

- Prefer modular designs: Look for tools with replaceable tips and clearer service options to reduce hidden maintenance.

- Check consistency tests: Favor models where buyers show batch weld tests and steady bead sizes in demonstrations.

- Watch for clear protections: Buy welders with documented thermal or current cutoffs to avoid unpredictable shutdowns.

The bottom line

Main regret: The combination of battery limits and inconsistent welds is the primary trigger causing mid-project stops and rework.

Why avoid: Those failures exceed normal category risk because they interrupt workflows more than typical mid-range alternatives.

Verdict: Avoid this unit if you need steady runtime or repeatable batch welds; consider it only for portable, occasional use.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.