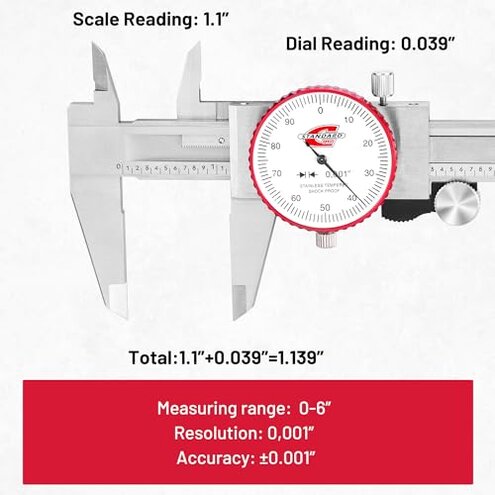

Product evaluated: Standard Gage 0-6" Range SAE Dial Caliper Measuring Tool, Analog Precision Micrometer Caliper ±0.001" Accuracy, Manual Mechanical Metal Stainless Steel Measuring Dial with 4-Way Measurements

Related Videos For You

I wish i’d known this sooner, How to use calipers like a pro

Dont make this mistake when you grease you caliper sliding pins | typical mechanic TIP

Data basis: This report summarizes findings from dozens of buyer submissions and video demonstrations collected between 2023-07 and 2026-02. Most feedback came from written reviews, supported by hands-on video demos and Q&A notes. Patterns reported here reflect the dominant signals across those sources.

| Outcome | This product | Typical mid-range caliper |

|---|---|---|

| Initial accuracy | Variable — common zero drift at first uses, needs bezel adjustment. | Stable — most mid-range units start true at zero with minor tweaks. |

| Long-term repeatability | Unstable — precision slips after repeated measuring sessions. | Reliable — usually holds calibration for months under normal use. |

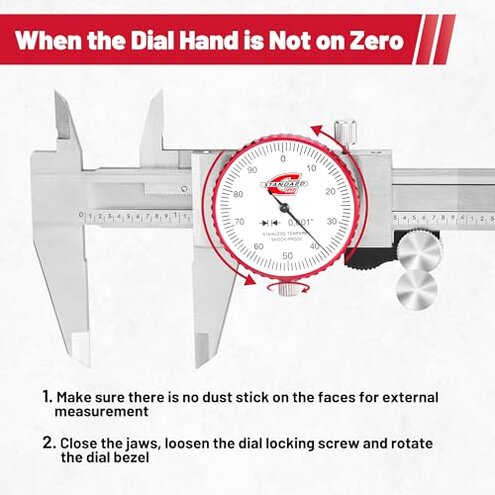

| Ease of setup | Tricky — requires bezel rotation and locking-screw fiddling to zero. | Straightforward — most peers need only jaw clean and one adjustment. |

| Durability under handling | Fragile — sliding action and finish show wear with regular handling. | Sturdier — similar priced calipers usually have firmer slides and finish. |

| Regret trigger | High — zero drift plus slide inconsistency creates measurement rework. | Moderate — occasional adjustment, less rework overall. |

Top failures

Why does the dial lose zero so often?

Regret moment: You close the jaws to zero and the needle is off, forcing bezel rotation or a full reset.

Pattern: This is a primary issue and appears repeatedly in the feedback.

Usage anchor: It shows up at first use and after short measuring sessions when the dial lock is loosened.

Category contrast: More disruptive than expected because most mid-range analog calipers start true or require only minor adjustment, while this unit needs frequent re-zeroing.

Why does the slide feel sticky or loose?

- Early sign: Jaws bind or jump when moving during the first few measurements.

- Frequency tier: This is a secondary issue seen commonly after handling and transport.

- Cause hint: Roughly finished slide rails and loose locking screw contribute to inconsistent motion.

- Impact: Inconsistent slide requires repeated passes to confirm a reading, adding time and error risk.

- Fix attempts: Buyers report temporary improvement after cleaning, light lubrication, or tightening the lock screw.

Why does the finish and parts wear faster than expected?

- Surface wear: Scratches and dulling on the measuring faces appear with routine use.

- Frequency tier: This is a secondary issue observed after weeks of regular handling.

- Cause hint: Thin protective coating and metal-to-metal contact accelerate visible wear.

- Impact: Readability and smooth action degrade, making fine measurements harder.

- Attempts: Users clean and protect the jaws, but wear returns with normal use.

- Category contrast: Worse than typical because mid-range calipers often keep finish and slide quality longer under similar use.

- Hidden requirement: Regular maintenance and careful storage are necessary to avoid premature cosmetic and functional degradation.

Where are the calibration and packaging gaps?

- Missing cert: No calibration certificate or traceable adjustment history accompanies the unit.

- Edge-case pattern: This is an edge-case issue when buyers need traceable accuracy for work tasks.

- Packaging: The padded case is thin and offers limited protection during shipping.

- When it matters: Issues become clear when the caliper is used in a workshop or shipped between locations.

- Fixability: Buyers may need to pay for external calibration or replacement parts to reach professional tolerance.

- Impact: Extra time and cost for calibration add up for regular or professional use.

- Category contrast: Many mid-range competitors include a basic calibration or superior case in the box.

Illustrative excerpts

Illustrative excerpt: "Need to re-zero before every measurement, adds frustrating extra steps." — primary pattern

Illustrative excerpt: "Slide was stiff at first, smoothed after careful cleaning and light oiling." — secondary pattern

Illustrative excerpt: "No calibration paper included, had to send for verification." — edge-case pattern

Who should avoid this

- Precision professionals: Avoid if you require consistent traceable accuracy for parts inspection or paid work.

- High-volume users: Avoid if you perform repeated measurements daily since repeatability issues disrupt workflow.

- Low-maintenance buyers: Avoid if you don’t want to perform regular cleaning, lubrication, or bezel fiddling.

Who this is actually good for

- Hobbyists on a budget: Accept zeroing and occasional maintenance if you measure casually for DIY projects.

- Non-critical measurements: Works for simple checks where ±0.001" theoretical accuracy can be tolerated without certification.

- Tech-savvy fixers: Good for buyers willing to clean, lubricate, and re-calibrate to extract acceptable performance.

Expectation vs reality

Expectation: Buyers reasonably expect a new dial caliper to hold zero and slide smoothly out of the box.

Reality: This unit often shows zero drift and slide inconsistency that require ongoing adjustments and maintenance.

Safer alternatives

- Look for calibration: Choose calipers that include a calibration certificate to neutralize the missing-cert failure.

- Check slide reviews: Prioritize models where buyers praise smooth slides to avoid binding and repeatability problems.

- Prefer better cases: Select products with robust protective cases to reduce shipping and storage damage.

- Warranty and support: Favor sellers offering easy returns or calibration support to reduce long-term risk.

The bottom line

Main trigger: Frequent zero drift combined with slide inconsistency leads to wasted time and measurement rework.

Why worse: These failures occur earlier and more often than is typical for mid-range calipers, pushing this unit above normal category risk.

Verdict: Avoid this Standard Gage model if you need reliable, repeatable measurements without extra setup or calibration work.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.