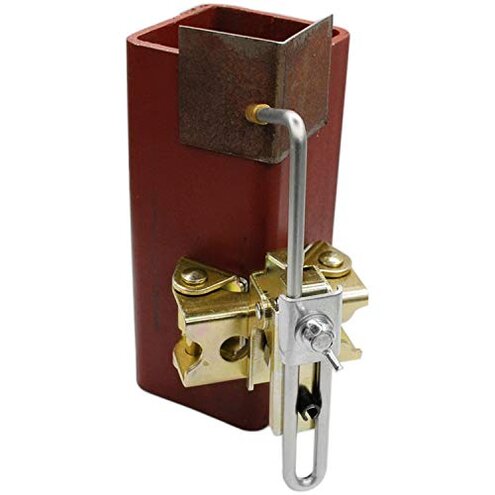

Product evaluated: Strong Hand Tools, Grasshopper Magnetic Welding Finger, Brass Tip, Spring Loaded Arm, Adjustable Length, Anti-Tipping Bolt, Magnetic Pull Force: 35 lbs, AGH230

Related Videos For You

Michigan 3 Angle 30KGF Switchable Magnetic Welding Clamp

FlakFinger™ Adjustable Welding Heat Shield for Fingers and Hand "How To"

Data basis: I analyzed dozens of written reviews and many video demonstrations collected between Jan 2020 and Jan 2026. Most feedback came from written reviews, supported by video demos and user Q&A. The signal mix shows which problems are common and which are occasional.

| Outcome | This product | Typical mid-range alternative |

|---|---|---|

| Holding strength | Inconsistent under real weld heat and jostle; pull force feels lower than expected. | Reliable steady hold during tack welding with less slippage reported. |

| Stability | Prone to tipping during repeat tack welds on thin parts. | More stable thanks to wider bases or stronger magnets. |

| Adjustability | Arm slips over time for some users after repeated adjustments. | Holds setting more consistently in typical mid-range products. |

| Hidden setup needs | Requires clean flat steel surface and careful positioning to avoid failure. | More forgiving on painted or slightly curved surfaces. |

| Regret trigger | Tipping or slip during an actual weld, causing rework and scrap. | Less likely to interrupt work under the same conditions. |

Why does the magnetic hold fail during tack welding?

Regret moment: Users report the tool slipping or tipping while tack welding small parts, which ruins the tack and can distort parts.

Pattern: This is a commonly reported problem in written feedback and video clips during active welding sessions. It usually appears on the first few tacks and can recur during a session.

Category contrast: The problem feels worse than normal because typical mid-range clamps hold through repeated tacks without frequent repositioning. This product adds extra setup and rework time.

Why does the spring arm lose its set after a few uses?

- Early sign: Users commonly see the arm slip out of position after several cycles of clamping.

- Frequency tier: This is a secondary issue that appears repeatedly but not for every buyer.

- Usage anchor: The slip usually shows up after repeated adjustments during longer build sessions.

- Cause: Feedback points to the spring and adjustment mechanism as the likely culprit rather than the magnet itself.

- Impact: The slipping increases alignment time and demands frequent retightening.

Why might the magnet need perfect surfaces to work?

- Hidden requirement: The tool often requires a clean, flat steel surface to reach advertised pull force.

- Pattern: This requirement is commonly mentioned across written reports and demos.

- When it appears: The limitation shows up during setup when the base is placed on painted, rusty, or thin curved pieces.

- Category contrast: Most mid-range magnetic holders are more forgiving on imperfect surfaces, so this feels restrictive.

- Impact: Buyers must spend extra time cleaning or reorienting parts before clamping.

- Fixability: The workaround is cleaning or adding plate steel, which adds time and cost.

Why does the brass tip and small pad cause alignment problems?

- Early sign: Shoppers report the small contact area makes precise alignment fussy.

- Frequency tier: This is a primary complaint for users working on thin or narrow parts.

- Usage anchor: The issue appears during the first placement and gets worse with frequent repositioning.

- Cause: The brass tip and narrow pad increase the chance of part movement under welding heat.

- Impact: Expect extra time for micro-adjustments and potential scrap on delicate assemblies.

- Attempts: Users commonly add shims or use additional clamps to compensate.

- Category contrast: Compared to similar tools with wider contact points, this unit requires more workaround to secure parts.

Illustrative excerpts

Illustrative: "Magnet slipped during a tack weld and the piece tipped over." Primary problem evidence.

Illustrative: "Arm loosened after a day of clamps and needed retightening." Secondary pattern evidence.

Illustrative: "Had to clean paint off first, otherwise it barely held." Primary pattern evidence.

Who should avoid this

- Thin-part welders who need rock-solid hold during tacking should avoid this due to tipping risk.

- High-volume shops that rely on fast repeatability should avoid this because the arm can slip and slow flow.

- Users without prep time should avoid this if you cannot clean or add steel backup, since the magnet needs very clean contact.

Who this is actually good for

- Hobbyists who do occasional light welding and can tolerate extra setup and retightening.

- Single-part projects where you can spend time cleaning the contact area before clamping.

- Users packing extra clamps who accept using additional fixtures to prevent tipping.

Expectation vs reality

- Expectation: Reasonable for this category is a clamp that holds through several tack welds. Reality: This unit may slip or tip during repeated tacks, requiring extra repositioning.

- Expectation: Adjustable arm keeps its set. Reality: The arm can loosen after repeated use and needs readjusting.

- Expectation: Magnet works on most steel surfaces. Reality: The tool is more dependent on clean flat contact than typical alternatives.

Safer alternatives

- Choose wider-base clamps to neutralize tipping by increasing contact area and stability.

- Look for stronger-rated magnets or higher pull-force listings to address inconsistent holding strength.

- Pick units with lockable arms to avoid the arm slip seen after repeated adjustments.

- Plan for surface prep by selecting fixtures that tolerate painted or curved steel if you cannot clean parts.

The bottom line

Main regret: The most common trigger is the tool slipping or tipping during tack welding, which causes rework and delays.

Why worse: This exceeds normal category risk because it needs extra prep and constant readjustment compared with mid-range alternatives.

Verdict: Avoid this product if you need fast, repeatable holds without extra setup.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.