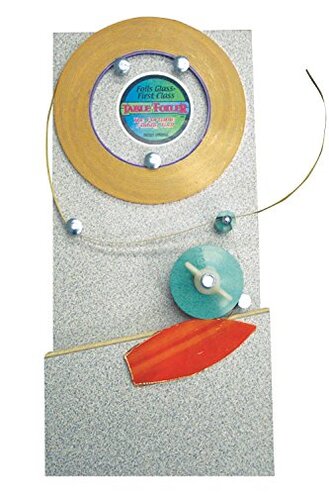

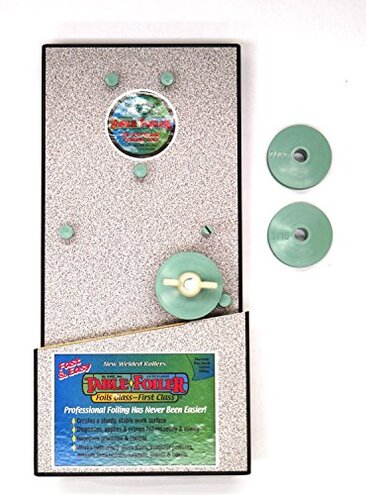

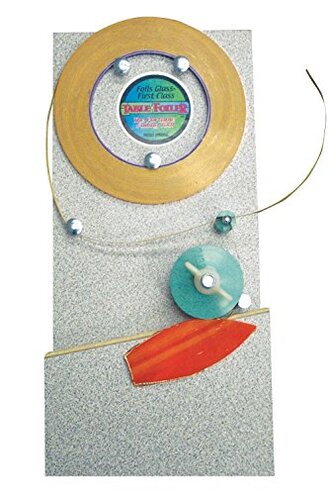

Product evaluated: Table Foiler for Stained Glass

Related Videos For You

Finish Foiling Fast with the Table Foiler

Preventing Foil Lifting :: Troubleshooting Stained Glass Edges

Data basis: This report is built from dozens of buyer comments and several video demonstrations collected between 2018 and 2024. Most feedback came from written reviews, supported by short user videos and seller Q&A. Signal mix shows patterns rather than single incidents.

| Outcome | Table Foiler | Typical mid-range alternative |

|---|---|---|

| Alignment accuracy | Unreliable — alignment drifts during longer runs and requires frequent re-centering. | More consistent — mid-range tools usually hold alignment through session-length work. |

| Compatibility with foil sizes | Tight fit — mounts need precise sizing and sometimes extra adapters to work. | Flexible — alternatives accept common foil widths without extra parts. |

| Build stability | Prone to wobble — stability degrades with frequent repositioning or heavier glass. | Sturdier — fewer complaints of wobble under normal use. |

| Setup time | Longer — extra calibration and trial runs commonly reported before usable results. | Quicker — mid-range models often work out of the box for typical projects. |

| Regret trigger | Frequent rework — misalignment and fit issues lead to extra soldering and time lost. | Lower risk — fewer interruptions and less rework expected. |

Top failures

Why does the foil wander during use?

Regret moment: Many buyers describe losing the centered foil mid-run, which forces pauses to reset placement.

Pattern: This is a commonly reported problem that appears repeatedly across written feedback.

Context: The issue shows up during longer sessions and worsens with continuous handling or when working on larger pieces.

Category contrast: Alignment failure is more disruptive than expected for this category because most mid-range foilers keep foil centered for full strips without constant adjustment.

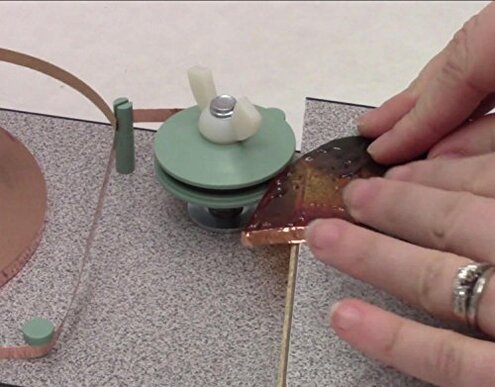

Will the mounts accept my foil sizes?

- Primary sign — mounts claim to fit several widths but buyers report a tight or loose fit.

- Frequency tier — this is a secondary issue, seen often enough to affect many buyers.

- Cause — sizing tolerances and simple plastic mounts lead to slippage or binding.

- Impact — when mounts fail, foil tracks unevenly and joints need rework.

- Hidden requirement — users commonly need extra adapters or shims to get a reliable fit.

Does the unit feel sturdy enough for regular studio use?

- Early signs — wobble during use or loose screws show up soon after first setup.

- Frequency — this complaint appears repeatedly across feedback sources.

- When it worsens — frequent repositioning or heavier panels increase instability.

- Cause — lightweight construction and small fasteners reduce rigidity under load.

- Attempts to fix — buyers report tightening hardware or adding weights, which adds setup time.

- Fixability — fixes are possible but require tools and effort not expected for plug-and-play tools.

Is the price justified for the performance?

- Buyer perception — many users find the cost high relative to the results.

- Scope — this is among the most common complaints about value for money.

- When noticed — buyers compare price versus performance after first few uses.

- Impact — perceived poor value leads some to return the product or buy aftermarket parts.

- Category contrast — mid-range alternatives often offer steadier alignment at similar or lower price points.

- Hidden cost — required adapters, repairs, or extra time increase total ownership cost.

- Decision friction — higher upfront price plus repair time makes regret more likely.

Illustrative excerpts (not direct quotes)

Illustrative: "Foil kept drifting after a few inches, had to stop and re-center constantly." — primary pattern

Illustrative: "Needed shims to fit common foil width, not as plug-and-play as expected." — secondary pattern

Illustrative: "Felt a wobble when I moved the table; tightened screws fixed but was annoying." — edge-case pattern

Who should avoid this

- Precision-first makers — if you need consistent centering without interruptions, avoid this unit.

- High-volume studios — if you foil for hours daily, the instability and rework risk are likely to slow you down.

- Buyers without tools — if you want true plug-and-play, avoid this unless comfortable adding shims or tightening hardware.

Who this is actually good for

- Occasional hobbyists — willing to tolerate periodic re-centering for lower-frequency projects.

- DIY improvers — buyers who enjoy modifying tools and can add shims or weights to stabilize the unit.

- Lightweight projects — those working with small panels where wobble and drift are less disruptive.

Expectation vs reality

Expectation (reasonable for this category): Foilers should hold foil centered through a standard strip without adjustments.

Reality: This unit commonly requires re-centering after short runs, which costs time and adds soldering rework.

Expectation: Mounts labeled for multiple widths will accept common foil sizes.

Reality: You may need adapters or shims to stop slippage, adding extra parts and setup time.

Safer alternatives

- Pick a sturdier base — look for models with heavier bases or metal mounts to reduce wobble.

- Check compatibility — choose products with documented fit for your foil widths to avoid adapters.

- Prioritize alignment guarantees — prefer tools from sellers who note sustained centering in their listings.

- Budget for extras — if buying this unit, set aside time and a small toolkit for shims and tightening.

The bottom line

Main regret trigger: Frequent misalignment and mount fit issues that cause repeat re-centering and added soldering.

Why it exceeds normal risk: Problems are more disruptive than expected because they persist across sessions and add hidden setup or parts cost.

Verdict: Avoid this unit if you need reliable, out-of-the-box centering; consider it only if you accept extra setup or DIY fixes.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.