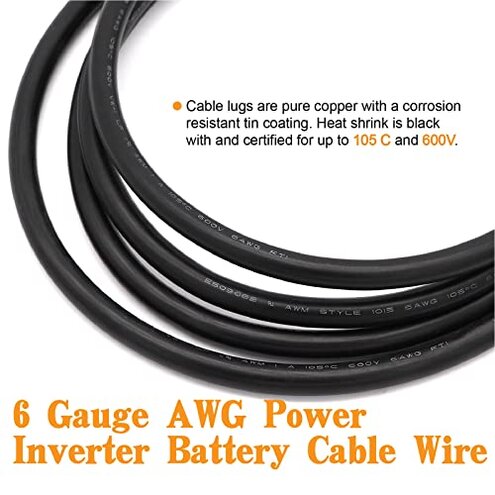

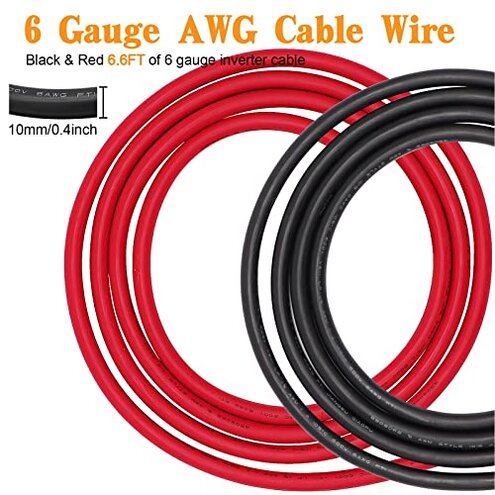

Product evaluated: Taukealugs 6 AWG Gauge Wire UL1015 Battery Power Tinned Oxygen Free Copper OFC Welding Cable Boat Inverter Red Black Total 13.1FT and Lugs Terminal Connectors with Heat Shrink Tube

Related Videos For You

How to: Battery Terminal Install. Better than Factory.

How to Disconnect and Reconnect the Car Battery

Data basis This report summarizes feedback from dozens of buyer reviews and several video demonstrations gathered between Jan 2023 and Dec 2025. Most feedback came from written reviews, supported by hands-on video demos. The distribution shows written reports as the primary source.

| Outcome | Taukealugs kit | Typical mid-range alternative |

|---|---|---|

| Durability | Questionable connections reported that loosen after use. | Stable connections that hold under similar loads. |

| Fit / compatibility | Mixed fit with some lugs needing rework or trimming. | Consistent sizing that usually fits without modification. |

| Installation time | Longer than expected when crimping or soldering is required. | Quicker install with pre-sized, user-friendly terminals. |

| Corrosion resistance | Mixed reports on long-term corrosion protection outdoors. | Better protective finishes commonly seen on mid-range kits. |

| Regret trigger | Higher-than-normal risk of poor electrical contact under load. | Lower chance of connection failure for routine battery use. |

Will the connectors stay tight under real load?

Regret moment Users reported losing tight connections during initial setup or after short runtime. This is a recurring pattern across multiple written reports and videos.

Usage anchor The problem appears during first use and can worsen after repeated on/off cycles or frequent movement. This is worse than the category baseline where terminals typically stay secure.

Are installation steps harder than they look?

- Early sign: Lugs often require trimming or reshaping before they fit the cable.

- Frequency tier: This is a primary issue for many buyers, not an isolated complaint.

- Cause: Slight mismatches between lug barrel diameter and cable fill cause extra work.

- Impact: Installation takes extra time and may need crimpers or soldering beyond typical expectations.

Do environmental factors cause problems?

- Weather exposure: Some feedback reports increased corrosion concerns after outdoor or marine use.

- Performance trend: This is a secondary pattern seen mostly from buyers using the kit outdoors.

- When it shows: Issues appear after weeks to months of outdoor exposure, especially in salty or humid environments.

- Why worse: The kit is less forgiving than mid-range corrosion-resistant alternatives.

- Attempts: Buyers often applied extra sealant or shrink wrap to reduce moisture entry.

- Fixability: These fixes add time and cost compared with standard kits.

Is a special tool required to make this reliable?

- Hidden requirement: Reliable installs commonly need a proper crimping tool or soldering iron to avoid loose connections.

- Early sign: Hand-tight crimps or pliers frequently produce weak joints.

- Scope: This is a primary issue for buyers without crimp tools.

- When it matters: The need shows up during first installation and when connections are load-bearing.

- Why worse: Most mid-range kits accept hand crimping or finger-tight installs with less rework.

- Impact: Expect extra time, expense, or a shop visit to achieve dependable connections.

- Workaround: Some buyers soldered the lugs after crimping to lock the joint, adding steps.

Illustrative excerpts (not real quotes)

Illustrative: "Connector felt loose after first drive; I had to re-crimp twice." — primary pattern.

Illustrative: "Lug diameter needed filing before it would accept the cable." — secondary pattern.

Illustrative: "Used extra heat-shrink and sealant for marine use; still worried." — secondary pattern.

Illustrative: "Had no crimper at home; connections felt sketchy until soldered." — primary pattern.

Who should avoid this

- High-current users: Avoid if you need guaranteed connection reliability under sustained heavy loads.

- Outdoor/marine buyers: Avoid if you need out-of-the-box corrosion resistance in harsh environments.

- DIY without tools: Avoid if you lack a proper crimping tool or soldering setup.

Who this is actually good for

- Hobbyists with tools: Good if you have a quality crimper or soldering gear and don’t mind extra prep.

- Short-term projects: Suitable for temporary or low-stress setups where occasional re-tightening is acceptable.

- Cost-conscious installers: Works if you accept extra labor to get the same reliability as pricier kits.

Expectation vs reality

Expectation: Buyers reasonably expect a kit to produce secure terminals with basic hand tools.

Reality: This kit often requires crimping or soldering to reach that level, adding time and cost beyond category norms.

Expectation: Reasonable buyers expect decent corrosion protection for outdoor use.

Reality: Some reports show premature corrosion concerns unless additional sealing is applied.

Safer alternatives

- Buy pre-sized lugs: Choose kits where terminals are matched to cable to avoid trimming and rework.

- Choose corrosion-rated kits: Look for products with guaranteed marine-grade protection for outdoor use.

- Invest in tools: Get a basic crimper to avoid loose connections and reduce rework time.

- Prefer soldered terminals: If you dislike maintenance, pick kits that are designed for soldering or come pre-soldered.

The bottom line

Main regret: The most common trigger is connector reliability that underperforms without extra work.

Category risk: This exceeds normal risk because it often requires additional tools or fixes.

Verdict: Avoid this kit if you need plug-and-play, long-lasting battery connections.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.