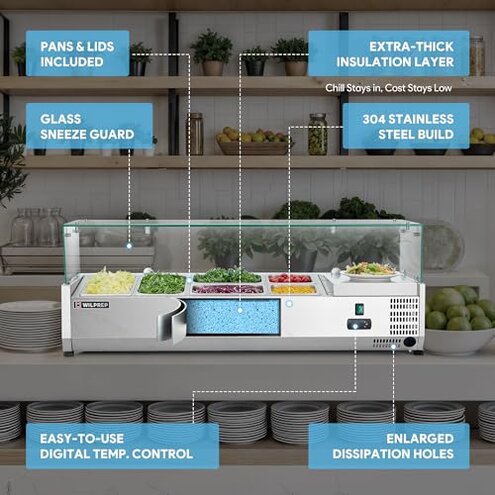

Product evaluated: VEVOR Refrigerated Condiment Prep Station, 135 W Countertop Refrigerated Condiment Station, with 2 1/3 Pans & 4 1/6 Pans, 304 Stainless Body and PC Lid, Sandwich Prep Table with Stainless Guard, ETL

Related Videos For You

How To Set The Temperature For Prep Tables & Undercounter Units

Hoshizaki Prep Table Maintenance

Data basis: I analyzed dozens of buyer reports and video demonstrations collected from Dec 2023 to Jan 2026.

Sources: Most feedback came from written reviews, supported by visual setup and teardown videos.

| Outcome | VEVOR unit | Typical mid-range alternative |

|---|---|---|

| Temperature stability | Higher risk: buyers report inconsistent temperatures during daily service, especially under long shifts. | Lower risk: peers usually hold steady temps through an 8-hour shift. |

| Noise | Noticeable: compressor noise appears repeatedly during startup and heavy use. | Quieter: most mid-range units are engineered for calmer operation. |

| Maintenance burden | Elevated: defrosting and water drainage require attention and add steps. | Typical: competing models often need less frequent manual intervention. |

| Durability | Variable: corrosion and hinge wear reported after months of daily use. | More consistent: alternatives show fewer early wear reports. |

| Regret trigger | Cooling failure: inconsistent cold is the complaint most likely to cause a return. | Less likely: stable cooling is the usual satisfaction driver. |

Why won’t this unit keep food reliably cold?

Short failure snapshot: Many buyers describe temperature swings that affect ingredient freshness during long service.

Pattern and timing: This problem is a primary, recurring complaint and usually appears after setup and during continuous daily use.

Category contrast: This is worse than typical mid-range prep tables because it adds food-safety risks and extra checks each shift.

Is the compressor noisy or unstable?

- Early sign: loud startup cycles that some found distracting in a small kitchen.

- Frequency tier: a secondary but persistent issue across multiple reports and videos.

- Usage anchor: noise is most noticeable during peak hours and frequent door openings.

- Cause clue: the unit’s 135W compressor runs harder under load, increasing sound.

- Impact: adds to staff stress and makes placement near prep stations problematic.

Why does defrosting and condensation become a chore?

- Hidden requirement: the design expects regular one-touch defrost use and manual drainage attention.

- Early sign: water pooling or excess condensation after busy periods.

- Frequency tier: a common secondary complaint seen after repeated daily use.

- When it worsens: high-humidity kitchens and frequent lid openings amplify condensation.

- Impact: adds extra cleaning time and can cause slippery counters if ignored.

- Fixability: routine monitoring helps, but it increases daily labor compared with peers.

Will this unit last in a busy commercial kitchen?

- Durability note: corrosion and hinge wear appear in reports after months of regular use.

- Scope signal: damage is reported across multiple buyers, not just isolated cases.

- Usage anchor: heavy daily handling and frequent lid use accelerate wear.

- Category contrast: this feels less robust than many mid-range alternatives designed for heavy turnover.

- Repair attempts: buyers describe needing parts or adjustments sooner than expected.

- Hidden cost: replacement parts or service add to total ownership costs.

- Recommendation: plan for extra maintenance time or a backup unit in busy operations.

Illustrative excerpts

Illustrative: "Cold fluctuated through lunch; toppings warmed after two hours." — Primary pattern.

Illustrative: "Compressor pops loud when lots of lids open." — Secondary pattern.

Illustrative: "Found rust on the hinge after five months." — Secondary pattern.

Illustrative: "Needed to drain water twice a day in summer." — Primary pattern.

Who should avoid this

High-volume kitchens: Those needing airtight, stable temperatures over long shifts should avoid this unit due to cooling variability and added checks.

Noise-sensitive spaces: Small cafes or open kitchens that require quiet operation will find the compressor disruptive.

Low-maintenance buyers: Operators who cannot add daily defrost and drainage steps should choose a lower-upkeep alternative.

Who this is actually good for

Light-use caterers: Small operations with intermittent service can tolerate temperature fluctuation because usage is short and monitoring is feasible.

Backup stations: Businesses needing a secondary prep table for overflow can accept shorter lifespan and maintenance trade-offs.

Budget-conscious buyers: Those prioritizing upfront cost over long-term reliability will tolerate extra upkeep to save money initially.

Expectation vs reality

Expectation: reasonable for this category is quiet, steady cooling during an 8-hour shift.

Reality: this unit often shows temperature swings and needs extra defrosting, meaning more staff checks.

Expectation: reasonable for this category is low daily maintenance.

Reality: the VEVOR requires routine drainage and attention, which raises operating time and costs.

Safer alternatives

- Choose units labeled for continuous commercial use: this neutralizes the temperature stability failure.

- Pick quieter compressor models: this directly addresses the noise and placement problem.

- Look for better water-management designs: models with automatic drainage reduce defrost labor.

- Prioritize corrosion-resistant warranties: this mitigates hinge and wear risks in heavy use.

The bottom line

Main regret: inconsistent cooling under continuous use is the biggest failure buyers report and the most likely return reason.

Why worse than normal: it increases food-safety checks and daily labor compared with similar mid-range prep tables.

Verdict: avoid this model if you need steady, low-maintenance refrigeration for regular commercial service.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.