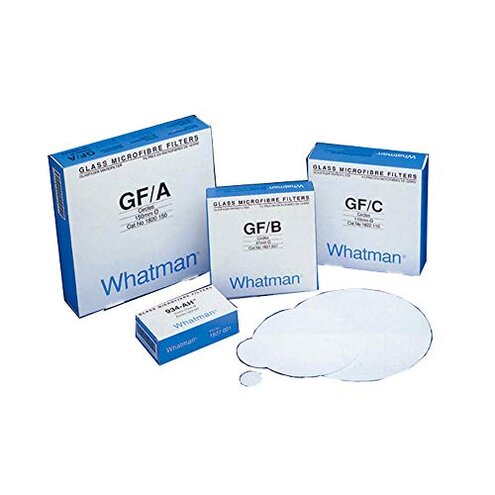

Product evaluated: Whatman 1827-021 Glass Microfiber Binder Free Filter, 1.5 Micron, 3.7 s/100mL Flow Rate, Grade 934-AH, 21mm Diameter (Pack of 100)

Related Videos For You

High-Quality Glass Microfiber Filter Media | I.W. Tremont

🌟 Filter Paper Chemistry (How to Fold a Fluted Filter paper )

Data basis: This report summarizes findings from dozens of user reviews and several video demonstrations collected between 2018–2025, with most feedback coming from written reviews and supported by visual test footage.

| Outcome | This product | Typical mid-range filter |

|---|---|---|

| Flow consistency | Variable — more clogging reports under particulate loads | Stable — designed for routine sample flow under similar conditions |

| Durability | Fragile handling on wet transfer, tears reported more often | Robust — fewer handling failures in normal use |

| Compatibility | Fit issues with some holders and vacuum rigs | Standard fit across common housings |

| Regret trigger | Clogging + waste — stops runs and raises replacement cost | Occasional clog but less disruptive and lower waste |

| Risk level | Higher-than-normal for routine particulate samples | Normal for a mid-range alternative |

Top failures

Will this clog during routine filtrations?

Regret moment: Users frequently hit a stop when flow slows or halts during normal sample filtering, forcing session restarts.

Pattern: This is a primary issue that appears repeatedly in written feedback and demo footage.

When it appears: Clogging shows up during first use with particulate or turbid samples and worsens under vacuum or long runs.

Category contrast: Clogging is more disruptive than expected for mid-range disposable filters because it causes session downtime and extra replacements.

Does it tear or fail when handled wet?

- Early sign: Edges fray or split when transferring a wet disc between tools.

- Frequency tier: This is a secondary issue reported often enough to affect workflow confidence.

- Usage anchor: Failures appear during removal from holders or when blotting after filtration.

- Cause: Handling friction and manipulation increase the chance of a tear.

- Impact: Tears create lost samples and extra filter use for the same job.

Will it fit my funnel or holder without extra work?

- Compatibility: Fit problems are an observed secondary pattern across different holders and rigs.

- Hidden requirement: Some buyers need precise seating or adapters to avoid leaks or poor seals.

- When it matters: Issues emerge at setup when swapping brands or using non-standard funnels.

- Why worse: This is less forgiving than typical filters that sit reliably in housings.

- Attempted fixes: Users mention trimming, spacers, or extra clamps as workarounds.

- Fixability: Workarounds add time and cost versus a straight replacement that fits.

Does it actually avoid shedding and inconsistent retention?

- Claim conflict: Some users report fiber traces or variable clarity despite manufacturer claims.

- Frequency tier: This is an edge-case issue but persistent enough to be noticed in demos.

- Usage anchor: Problems appear after multiple uses or with sticky/viscous samples.

- Cause: High particulate loads and incomplete pre-rinsing increase visible residue.

- Impact: Residue leads to extra rinses and possible downstream contamination concerns.

- Attempted fixes: Pre-wetting and extra rinses reduce signals but add time.

- Why worse: This is more annoying than expected for filters sold as low-shedding.

- Hidden cost: Extra steps create a time penalty for routine workflows.

Illustrative excerpts (not actual quotes)

"Flow stopped mid-run, wasted sample and had to restart." — Primary

"Disc tore when pulling it out wet, ruined the batch." — Secondary

"Needed an adapter to seat the filter, unexpected extra parts." — Secondary

"Had to rinse twice to avoid residue in the filtrate." — Edge-case

Who should avoid this

- High-throughput labs: If you run many samples, clogging and tear risks add significant downtime.

- Field users: Portable setups will suffer from the need for adapters and careful handling.

- Time-sensitive workflows: Any extra rinses or repeats make this less suitable than sturdier alternatives.

Who this is actually good for

- Occasional hobby use: Users filtering few samples can tolerate extra steps and occasional re-runs.

- Non-critical tests: If contaminant traces are acceptable, the product's performance is usable.

- Cost-conscious buyers: If you accept extra handling time, the pack price per disc can be economical.

Expectation vs reality

Expectation: Buyers reasonably expect consistent flow and single-run finishes for routine samples.

Reality: You may see stopped runs, extra rinses, or disc tears that add time and replacements.

Expectation: A mid-range filter should fit common holders without modification.

Reality: Some buyers need adapters or trimming to get a proper seal, adding hidden cost.

Safer alternatives

- Choose robust fit: Look for filters marketed with standardized fit or with adapter kits included to avoid seating issues.

- Prioritize clog resistance: Pick alternatives labeled for high particulate loads if you filter turbid samples frequently.

- Opt for reinforced discs: Select filters noted for wet handling durability to prevent tears during transfer.

- Request demo footage: Prefer sellers that provide real-use videos showing flow and handling before buying.

The bottom line

Main regret: The combination of clogging and handling fragility is the dominant cause of buyer disappointment.

Why it matters: These failures add extra steps, replacements, and time compared with typical mid-range filters.

Verdict: Avoid this product if you need reliable, high-throughput, or time-sensitive filtering without added adapters or rework.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.