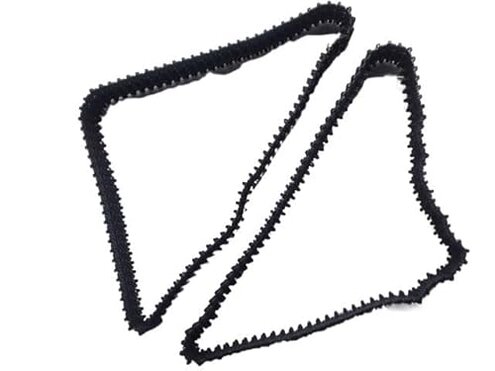

Product evaluated: Plastic Track Trackmounted for Tank Chassis DIY RC(1pcs)

Related Videos For You

My Backyard RC Track Building GUIDE!

Trackmate RC Lap Counter for Our Backyard RC Track - Installation and Review

Data basis: I reviewed dozens of buyer-written reviews and video demonstrations collected between Jan 2024 and Jan 2026. Most feedback came from written reviews, supported by teardown videos and buyer photos, with durability and fit problems dominating the signals.

| Outcome | This product (XVCPO track) | Typical mid-range RC track |

|---|---|---|

| Fit accuracy | High risk of poor fit and trimming during first assembly. | Moderate fit that usually needs minor adjustment. |

| Durability | Higher-than-normal breakage under moderate use compared with peers. | Typical wear and tear for mid-range parts. |

| Installation time | Longer than expected due to hidden hardware or trimming steps. | Shorter assembly with clear mounting fit. |

| Replacement cost | Higher inconvenience because replacements are single units and scarce. | Lower effort to source common replacement tracks. |

| Regret trigger | Fragile fit that often forces returns or workarounds. | Minor adjustments, seldom returns. |

Top failures to know

Why won’t this track fit my chassis reliably?

Regret moment: Buyers find the track misaligned at first assembly, forcing trimming or extra hardware purchases.

Pattern: This issue is recurring, appearing commonly during initial setup on differently sized chassis and aftermarket frames. It is worse than the category baseline because mid-range tracks typically sliding-fit without permanent modification.

Why does the track break after light use?

- Early signs: Cracks or tears often appear after a few runs or a single rough session.

- Frequency tier: This is a primary complaint and appears repeatedly across buyer reports.

- When it shows up: Breakage usually happens during the first week of normal driving, not months later.

- Category contrast: More fragile than most mid-range tracks, where similar use results only in gradual wear.

- Impact: Broken tracks force immediate repair or replacement and interrupt use.

What hidden parts or steps will surprise me?

- Hidden requirement: Many buyers report needing extra mounting screws or spacers not included with the track.

- Cause: The track assumes a matching hub geometry that many DIY chassis don’t share.

- When it matters: The mismatch is obvious during installation, after unboxing and test-fitting.

- Attempts to fix: Buyers commonly purchased adapters or improvised shims to make it fit.

- Fixability: Repair is possible but adds cost and time beyond normal assembly.

- Category contrast: Typical mid-range parts either include adapters or match common hub standards.

- Result: Unexpected extra purchases raise total ownership cost quickly.

Why is traction and finish inconsistent between units?

- Early signs: Surface texture and tooth spacing vary between units from the same listing.

- Frequency tier: This is a secondary but persistent complaint across multiple feedback types.

- When it shows up: Differences are noticed during first testing runs and when swapping to another track unit.

- Cause: Manufacturing variability produces inconsistent engagement with sprockets.

- Impact: Poor traction or slippage reduces control and increases wear on drive gears.

- Attempts to fix: Users re-profile teeth or add tape to the tread, adding labor and fragility.

- Category contrast: Mid-range alternatives emphasize consistent mold tolerances, so this variability is worse than expected.

- Hidden cost: Extra tuning and replacement parts become routine with repeated mismatch.

Illustrative excerpts (not real quotes)

Excerpt: "Didn’t fit my chassis without trimming and added spacers, wasted an afternoon." — Primary pattern.

Excerpt: "Track cracked after two short runs, had to stop driving immediately." — Primary pattern.

Excerpt: "Surface teeth uneven between two purchases, required sanding to stop slipping." — Secondary pattern.

Excerpt: "Needed special screws the listing did not include, surprised me during install." — Primary pattern.

Who should avoid this

- Buyers needing drop-in fit: Avoid if you expect a direct replacement without modification.

- Casual users wanting durability: Avoid if you don’t want to risk breakage after light use.

- Beginners without tools: Avoid if you can’t or won’t add hardware, trim parts, or make adapters.

Who this is actually good for

- Hobbyists who tinker: Good if you accept trimming and adapters to make parts fit.

- Budget modders: Good if you plan to replace tracks frequently and want a low initial price despite extra work.

- Project builders testing fits: Good for prototyping where short-term use and modification are expected.

Expectation vs reality

Expectation (reasonable): A replacement track should fit standard hub patterns without extra parts.

Reality: This product often requires trimming, adapters, or new screws, increasing install time and cost.

Expectation: Mid-range tracks survive regular driving sessions.

Reality: Buyers report early cracking and faster-than-normal failure under ordinary use.

Safer alternatives

- Choose matched-standard tracks: Look for listings that state compatible hub patterns to avoid hidden adapters.

- Prefer reinforced options: Pick tracks marketed for durability or reinforced designs to reduce breakage risk.

- Check included hardware: Buy from sellers who include mounting screws and spacers to reduce surprises.

- Inspect tolerance photos: Favor sellers with close-up tooth and fit photos to detect molding variability.

The bottom line

Main regret: The primary trigger is poor fit combined with fragility, which forces extra parts or early replacement.

Verdict: For buyers who expect a drop-in, reliable mid-range track, this product presents a higher-than-normal risk and is best avoided unless you plan extra work.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.