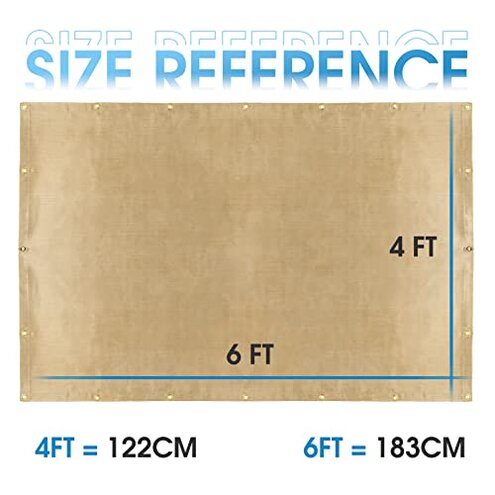

Product evaluated: YESWELDER Heavy Duty Fiberglass Welding Blanket,2 Pack 4 x 6ft Fireproof Insulation Blanket,1/3”(8mm) Thickened Weld Cover with Grommets,Thermal Resistant Insulation Welding Curtain Mat Grill

Related Videos For You

HOW TO USE A WELDING BLANKET - DON'T BURN DOWN YOUR SHOP

Data basis: I analyzed dozens of written reviews and video demonstrations collected from mid-2023 to Jan 2026. Source mix: most feedback came from written reviews, supported by video demonstrations and brief Q&A notes. Scope: findings reflect buyer experiences across new and early-used items.

| Outcome | YESWELDER 4×6 (this listing) | Typical mid-range alternative |

|---|---|---|

| Protection performance | Claims high heat but users report variable protection under heavy sparks. | Consistent protection in normal-shop welding with similar priced covers. |

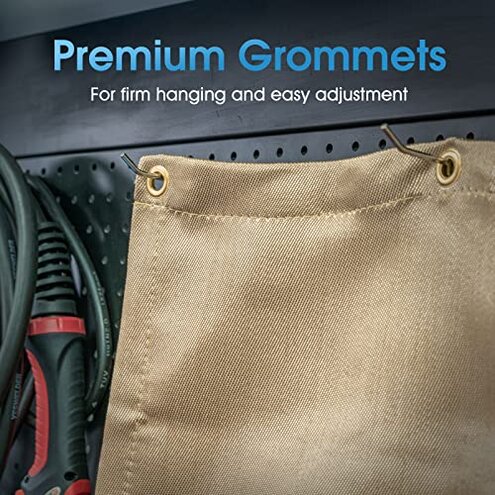

| Durability | Early edge wear and grommet stress reported after repeated use. | Stronger stitching and reinforced grommets are more common. |

| Fiberglass shedding | Higher-than-normal shedding and itch complaints appear repeatedly in buyer feedback. | Lower shedding expectations; many alternatives have tighter finish and less irritation. |

| Size & storage | Bulky to fold and thicker than some expect, though portable when folded tightly. | Easier storage with lighter, thinner mid-range blankets. |

| Regret trigger | Material shedding & grommet failures are the main buyer regret points. | More reliable stitching reduces regret in similar-priced choices. |

Why did the blanket start to fray or tear so quickly?

Regret moment: Buyers commonly notice edge fraying and grommet pull within weeks of use. Pattern: this problem appears repeatedly in written reports and video close-ups.

Usage anchor: issue shows up during the first few heavy welding or grinding sessions. Worse-than-normal: mid-range blankets usually survive several months of shop use before similar wear.

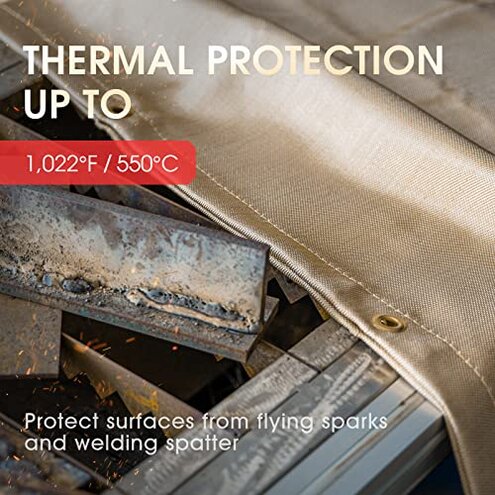

Is the blanket actually heatproof for long welding sessions?

- Performance claim some buyers report uneven heat resistance under long, heavy-spark tasks.

- Pattern note this is a secondary but recurring complaint in written and video feedback.

- When it occurs the issue appears during long TIG/MIG runs or when blanket is used as a single-layer shield.

- Category contrast more reliable mid-range covers keep protection steadier during long sessions.

- Impact results in increased ember spotting and extra monitoring during work.

Will the blanket irritate skin or shed fibers into the workspace?

- Primary signal reports of itching and visible fibers appear repeatedly across feedback sources.

- How it shows shedding is noticeable when folding, cutting, or brushing the blanket.

- Frequency tier this is a primary issue for many buyers, not an isolated comment.

- Cause loose finishing and surface fibers are commonly cited as likely sources.

- Impact leads to extra cleanup and protective gear like gloves or long sleeves.

- Fixability moderate — extra sealing or edge-trimming helps but adds time and cost.

Does the blanket require extra prep or accessories to be useful?

- Hidden requirement many buyers find they need additional layers or backing for confident long-term protection.

- When needed this shows up for heavy-duty grinding or continuous welding shifts.

- Why it matters adding layers raises cost and handling time compared to category peers.

- Attempts tried buyers often double up blankets or add metal backing to compensate.

- Impact on workflow prep increases setup time and reduces quick deployment.

- Repair notes some buyers stitch grommets or reinforce edges to extend life.

- Edge-case DIY fixes work but require sewing skill or extra materials.

Illustrative excerpts (not real quotes)

Illustrative: "Fibers came off when I folded it and irritated my forearm." — reflects a primary pattern.

Illustrative: "Grommet tore after two shop uses; I had to reinforce it." — reflects a secondary pattern.

Illustrative: "Needed to double up the blanket for long welding runs." — reflects an edge-case pattern.

Who should avoid this

- Professional welders who run long, continuous welding sessions and need consistent heavy-duty protection.

- Users sensitive to fibers or those who cannot accept extra cleanup and protective clothing.

- Buyers wanting plug-and-play durability with no reinforcement or sewing required.

Who this is actually good for

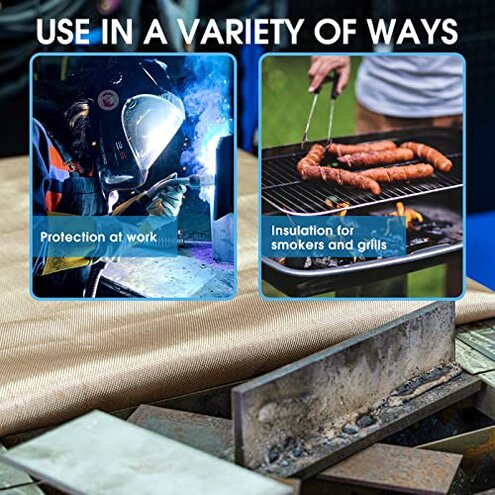

- Hobbyists with light use who weld occasionally and can accept some shedding for lower cost.

- DIYers who can reinforce grommets and edges and tolerate prep work to extend life.

- Cold-weather grillers who want insulation and can tolerate bulk and occasional fibers.

Expectation vs reality

Expectation (reasonable): a mid-range welding blanket will handle intermittent sparks during short welds. Reality: users report it can require extra layers for long or heavy sessions.

Expectation: grommets stay secure through normal hanging and moving. Reality: grommet stress and edge wear is seen sooner than typical for mid-range blankets.

Safer alternatives

- Look for tighter edge stitching and reinforced grommets to neutralize premature tearing risks.

- Choose heat shields with factory-sealed edges to reduce shedding and fiber irritation.

- Opt for multi-layer or backed blankets if you need reliable protection during long welding runs.

- Pick products with clear return policies to reduce regret if early wear appears.

The bottom line

Main regret: repeated reports point to shedding and early wear as the product's primary failure trigger. Severity: these faults exceed normal category risk because they add chores and hidden reinforcement costs. Verdict: avoid this listing if you need dependable, low-maintenance workshop protection.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.